|

|

|

|

| Home | Light Duty Machines | Heavy Duty Machines | Special Machines | Table-Up Machines |

| Tooling & Broaches | Broaching Examples | Used Machines | Production Broaching | Contact |

| (Click for large view) | ||

Broach Tooling and Broach Tool Examples |

|

SMF-232 Infeed Table : A good choice for broaching deep or wide flats, using economical short broaches. Automatic infeed cycle combined with multiple full broach strokes, produce a successively deeper cut until the proper dimension is reached. |

||

|

SMF-223 Tilt Table : Tilt function of this table permits easy piece part reloading away from the broach path. Ideal for broaching flats and slots, plus straddle broaching ( making parallel cuts on opposite sides of a part ). Part clamping is embedded in the machine sequence. This fixture is shown utilizing a Zagar brand indexing unit. |

||

|

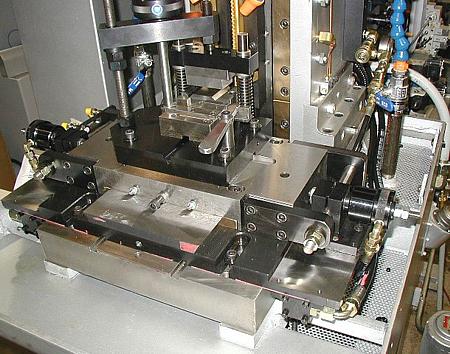

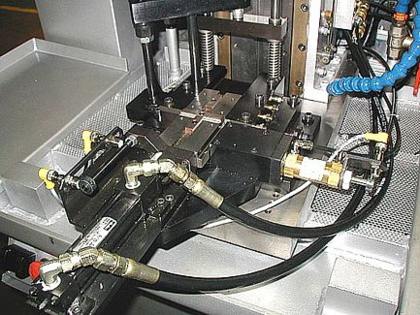

SMF-225 Shuttle Table : Various manual or automatic fixtures can be mounted onto the shuttle table so work pieces can be loaded and automatically “shuttled” into a precise broaching position……and then back for reloading while the machine ram is returning to it’s home position thus reducing machine cycle time. Automatic piece part ejection is also available. |

||

|

SMF- 252 Air Operated Broach Puller : For Instant, positive broach holding. Air actuated jaws provide more reliable, immediate, automatic grip release action over a conventional spring actuated type. And no chip clogging. A constant, low volume air stream forces chips out of the puller mechanism after each stroke, preventing interference with the broach engagement. The Miles air-operated puller can be mounted on any vertical or horizontal broaching machine and accommodates broach shank capacities from 3/16" to 1" Dia. |

||

|

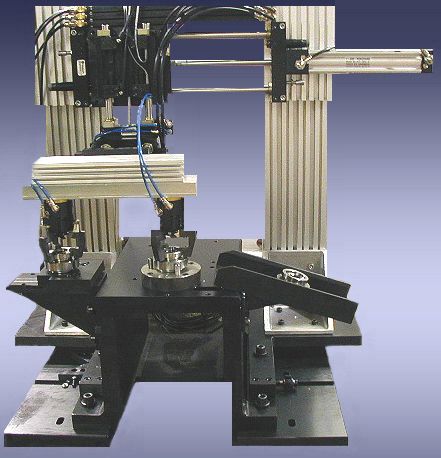

Pick and Place Automation : Ty Miles automation systems can designed and added to a variety of new machines, or existing machines already out in the field. Combine pick and place part loading and unloading with Inbound and Outbound part conveyors, to achieve a totally automated broaching system. |

||

|

Standard Flat Broach : A standard flat broach comes closest to being a multi-purpose tool because it can cut a multitude of surface depths and widths by making simple fixture adjustments. Miles versatile Broach Holders accommodate either Flat or Slot broaches. The precision keyed and ground holders are available in lengths for machines strokes ranging from 12" to 60". |

||

|

Standard Straddle Broach : A straddle broach cuts surfaces in two or more planes simultaneously. It’s the best method when separate cuts must have a precise dimensional relationship. Miles stocks a wide range of STANDARD straddle broaches. |

||

|

Standard Slot Broach : Slotting broaches can quickly produce a precision slot to any desired width and depth. Extra deep slotting can be achieved by multiple passing the machine until the proper depth of cut is reached. As shown in the photo on the left a Side Spacer is required on each side of the broach in order to fill up the holder opening. Spacers are easily made in your toolroom, or can be furnished by Miles. |

||

|

©

2018 Ty Miles, Inc. No duplication or reproduction without

author's consent. All Rights Reserved. 9855 Derby Lane, Westchester IL 60154 USA / 708-344-5480 stevem@tymiles.com |